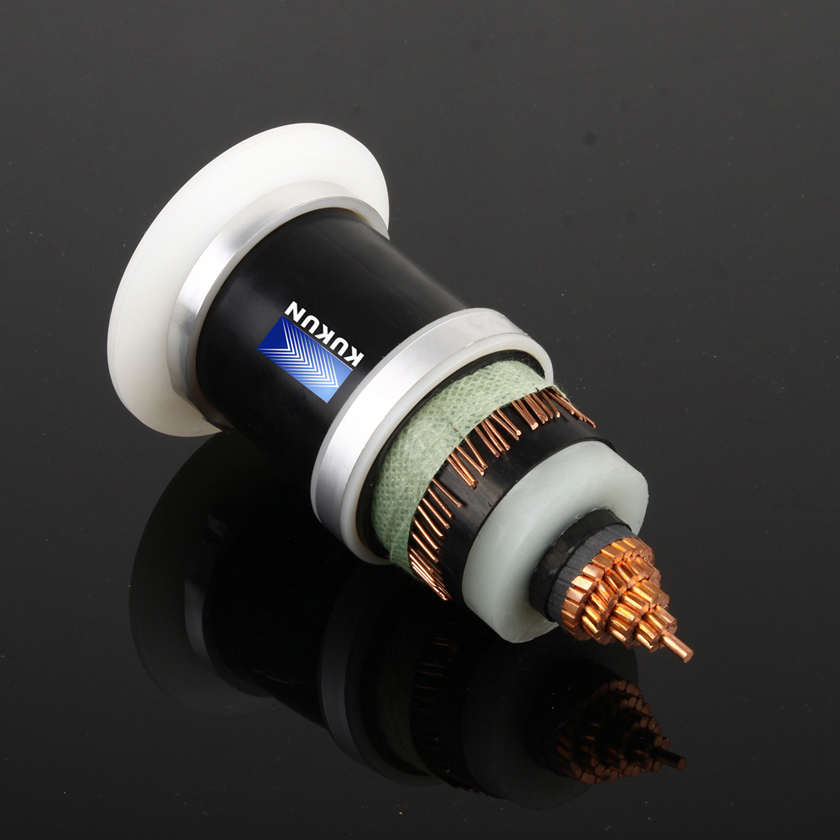

18/30kV CU/XLPE/PVC(or PE) Power Cable

Description

Construction: Compacted stranded circular copper conductor, extruded semi-conducting compound as conductor screen, cross-linked polyethylene(XLPE) insulation, semi-conducting compound as insulation screen, copper tape or combination of copper wire and tape as metallic screen, three cores assembled together with non-hygroscopic polypropylene filler, wrapped with binder tape, PVC or PE outer sheath.

|

Type |

Description |

No. of cores |

Nominal cross section of conductor |

|

YJV |

Copper conductor/XLPE insulation/PVC outer sheath Power Cable |

1 or 3 |

50~800mm2 |

|

YJY |

Copper conductor/XLPE insulation/PE outer sheath Power Cable |

1 or 3 |

50~800mm2 |

|

ZA-YJV ZB-YJV ZC-YJV |

Copper conductor/XLPE insulation flame-retardant Power Cable |

1 or 3 |

50~800mm2 |

|

WDZA-YJY WDZB-YJY WDZC-YJY |

Copper conductor/XLPE insulation Low Smoke Halogen Free or Zero Halogen (LSHF or LSZH) flame-retardant Power Cable |

1 or 3 |

50~800mm2 |

Application

The cable is used for fixed installations such as electric power distribution networks or industrial installations, which is laid indoors, outdoors, in tunnel or in cable trench, unable to bear external mechanical force.

Single core cable in magnetic duct is not permissible.

Manufacturing Standards

GB/T 12706-2008, IEC 60502-2